Arc thermal sprayed Induction base

Left : Arc thermal spray applied, Right : normal bottom

Left : Arc thermal spray applied, Right : normal bottom

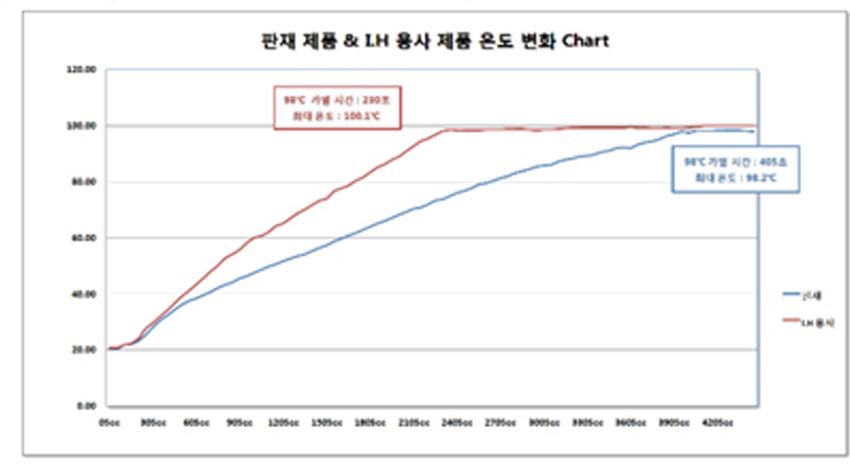

Temperature measurement

Output measurement

Output : 851w

Temperature measurement

Output measurement

Output : 1,247w